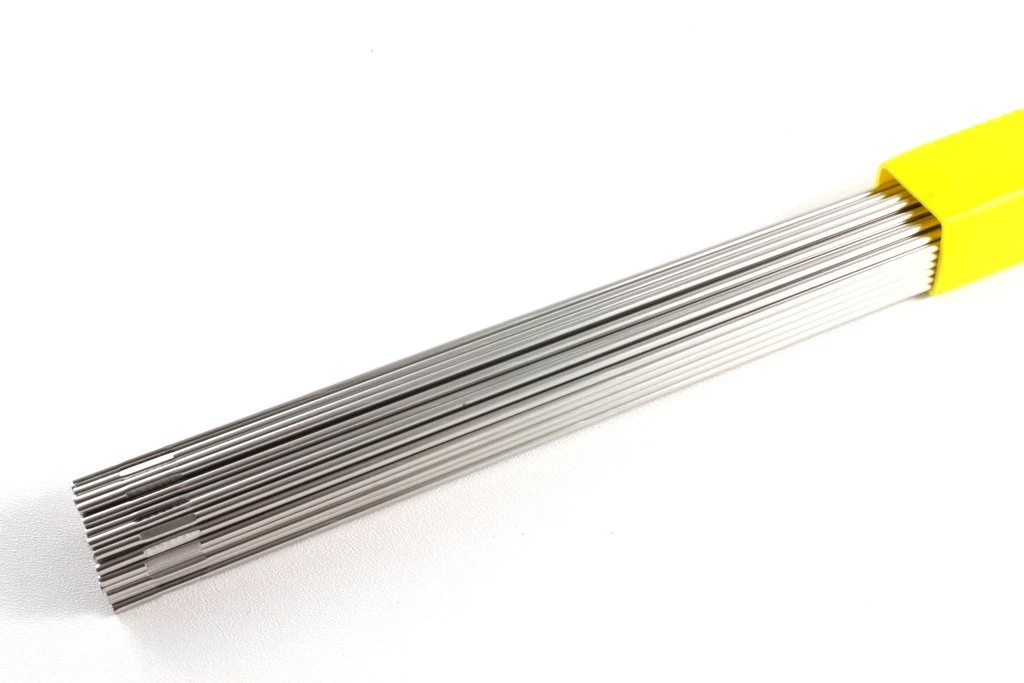

AWS A5.9 ER308

YB/T 5092 H08Cr21Ni10Si

GB/T 4241 H08Cr21Ni10Si

JIS Z3321 Y308

BS EN ISO 14343-B-SS308

Introduction

It is stainless steel MIG welding wires. The welding metal has good mechanical properties and resistance to intergranular corrosion, and good weld crack resistance.

Uses:

Used for welding of 18-8, 18-12 and 20-10 austenitic stainless steel. It is for welding same composition base material, specially for 304 stainless steel.

Chemical Composition:

C | Mn | Si | S | P | Cr | Ni | Mo | Cu |

0.05 | 1.79 | 0.48 | 0.013 | 0.022 | 19.72 | 9.40 | 0.008 | 0.09 |

Mechanical Properties

Tensile Strength Rm (MPa) | Elongation A(%) |

580 | 42 |

Notes

1. For good welding mechanical properties, welding protective gas adopts Ar+2%O2, gas flow is 20-25L/min.

2. It adopts DC reverse connection for welding and welding arc length is 4mm-6mm. Too long welding arc is easy to produce blowholes and other defects. Too short arc will produce poor infiltration.

3. Welding linear power directly affects mechanical property of welding metal and crack proof. It should be paid more attention.

4. Strictly remove grease, moisture and other impurity on welding body.