Hand-held optic fiber laser welding machine

Product instruction:

Hand-held optic fiber welding has a lower production compliance rate. However, hand-held welding machine is the best choice for the production workshops engaged in small-scale processing or non-large-scale welding. There is no need to set up equipment to deploy the welding station, which takes up little space. The important point is that the welding products of small workshops are diversified and the shape of the products is flexible. Hand-held laser welding machine can fully meet those requirements.

The hand-held laser welding machine replaces the previously fixed light path with a hand-held torch, overturning the previous working mode of the laser welder. This mode of operation not only facilitates the welding of molds, advertising characters, kitchen utensils, etc, but also allows for laser welding in outdoors .

Hand-held laser welding machine applications:

Widely used in kitchens, household appliances, advertising, molds, stainless steel doors and windows, crafts, household items, furniture, auto parts and many other industries.

Advantages of hand-held laser welding machine:

1. It is easy to operate and can be welded by hand. No need to cost much money to hire a welding master .

2. Suitable for small-scale production: Hand-held laser welding machines have lower production compliance rates than fully automated equipment deployments. However, for the production workshops engaged in small-scale processing or non-large-scale welding, manual laser welding is the best choice. There is no need to set up equipment to deploy the welding station, which takes up little space. The important point is that the welding products of small workshops are diversified and the shape of the products is flexible. Manual laser welding can fully meet the needs of this production, and the compliance is better.

3. Low maintenance cost: Hand-held laser welding, no need good soldering station, low material cost, low energy consumption, low equipment deployment and maintenance costs. In the same working environment, we need to spend a lot of time to maintain the soldering station, but as long as there is a hand-held laser welding machine in the manual laser setting equipment deployment, we can use to weld. As for replacement, the cost of replacing parts is low too.

Hand-held laser welding machine features:

The hand-held welding head is flexible and convenient for outdoor welding.

The operating mode of the hand torch allows the work-pieces to be welded at any angle from any location.

Intelligent switching of dual light paths, evenly distributing energy according to different time and different light.

Suitable for spot welding of various complex welded joints and various equipment.

CCD camera monitoring system for easy viewing and precise positioning.

Hand-held laser welding machine applications:

Widely used in kitchens, household appliances, advertising, molds, stainless steel doors and windows, crafts, household items, furniture, auto parts and many other industries.

Welding effect pictures:

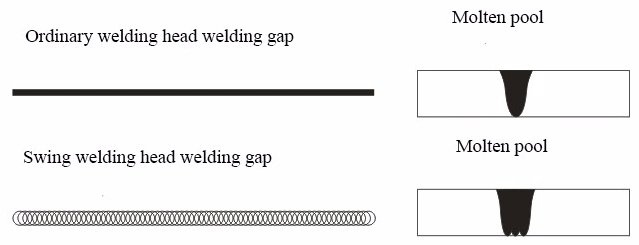

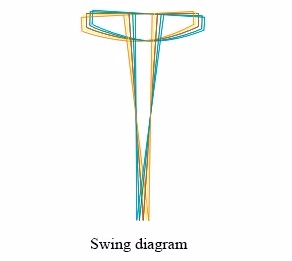

Ordinary welding head and swing welded joint

The oscillating head can obtain a wider weld than the ordinary head, which can reduce the requirement of the hand welding for the worker.

The oscillating head adopts a high-speed rotation mechanism to achieve material agitation, achieve the effect of stirring welding, and can be compatible with a larger gap than a common head.

Welded aluminum alloy swing heads have an unparalleled advantage over ordinary heads.

The common head is compatible with a gap having a gap smaller than the thickness of the material to be welded by 1/5.

The oscillating head can be compatible with a gap having a gap smaller than 1/3 of the thickness of the material to be welded.

Equipment name and electricity demand:

| Equipment Model | Equipment name | Electricity demand |

| DPH-500SCBD-CX-W | 500W hand-held swing welding machine(Max) | AC 220V10A |

| DPH-1000SCBD-CX-W | 1000W hand-held swing welding machine(Max) | AC 220V20A |

| DPH-1500SCBD-CX-W | 1500W hand-held swing welding machine(Max) | AC 220V30A |

| DPH-500SCBD-RC-W | 500W hand-held swing welding machine(Raycus) | AC 220V10A |

| DPH-1000SCBD-RC-W | 1000W hand-held swing welding machine(Raycus) | AC 380V10A |

| DPH-1500SCBD-RC-W | 1500W hand-held swing welding machine(Raycus) | AC 380V20A |

Material penetration table:

| Laser power | Stainless steel | Carbon Steel | Galvanized sheet | Brass | Aluminum |

| 500W | ≤1mm | ≤1.5mm | ≤1.5mm | 0mm | 0mm |

| 1000W | ≤2mm | ≤3mm | ≤2mm | ≤1.5mm | ≤1.5mm |

| 1500W | ≤3mm | ≤4mm | ≤2.5mm | ≤2.5mm | ≤2.5mm |

Equipment pictures:

type 1 :

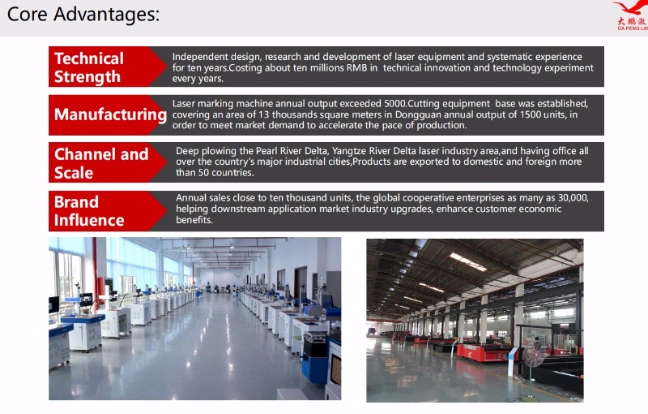

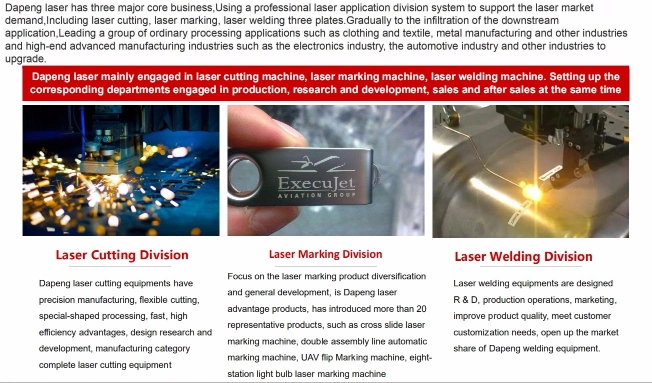

company profile