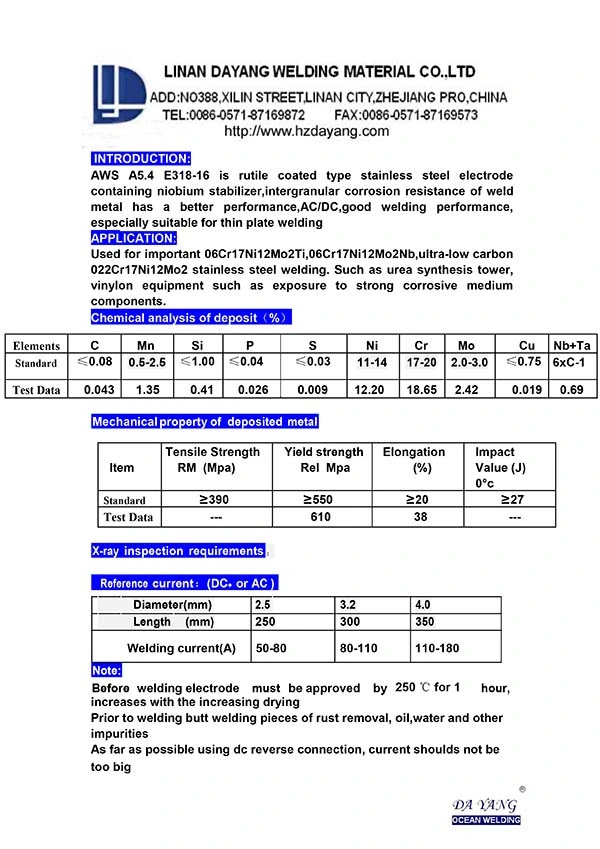

CE ISO SGS approved Welding Electrode aws E318-16

| Stainless Steel Electrode | ||||||||

| Item NO. | GB/TB | AWS | ||||||

| WEA212 | E318-16 | E318-16 | ||||||

| Chemical composition of Deposited metal(%): | ||||||||

| C | Mn | Si | Cr | Ni | Mo | Cu | S | P |

| ≤0.08 | 0.5-2.5 | ≤0.90 | 17.0-20.0 | 11.0-14.0 | 2.0-3.0 | ≤0.7 | ≤0.030 | ≤0.040 |

| Mechanical Performance of deposited Metal: | ||||||||

| Rm(Mpa) | A(%) | |||||||

| ≥550 | ≥25 | |||||||

| Reference Current:(DC or AC) | ||||||||

| Diameter (mm) | Φ2.5 | Φ3.2 | Φ4.0 | Φ5.0 | ||||

| Current (A) | 50-80 | 80-110 | 110-160 | 160-200 | ||||

| Notes: (I)Please bake WEA212 Stainless Steel welding electrode for 1 hour at 150°C before welding. (II)We suggest you to do the welding by DC and control the current to avoid redenning problem of rodes. By AC, the depth will not be enough. | ||||||||

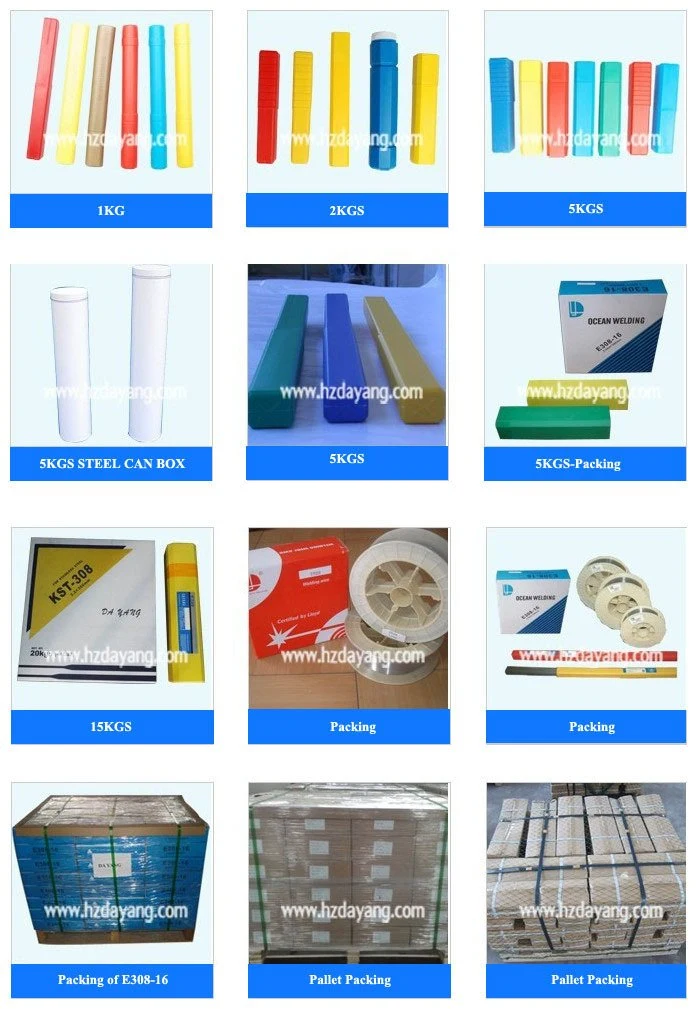

Packaging Details:

Inner packing: 1) 2.5mm x 300mm, 1-5kg/ plastic bag+ inner box

2) 3.2mm x 350mm, 1-5kg/ plastic bag+ inner box

3) 4.0mm x 350mm, 1-5kg/ plastic bag+ inner box

Delivery Detail: Within 8-20 days after confirmation

Our Services

OEM is acceptable;

Samples are provided for free.

Product Show

Packing

Company Information

Lin'an Dayang Welding Material Co., Ltd., located in the western part of Hangzhou, was established at the beginning of this century. We possess a production line of oil pressure unit, which can produce 5000 ton stainless steel welding electrodes. Our company owns rich technical resources to design, research and mainly produce special type of electrodes with complete models.

The electrodes are mainly exported and the amount is up to 2000 tons per year on average. Our customers are mainly from Germany, Indonesia, Singapore, Philippines, Vietnam, Thailand, Bengal, and Egypt. They think highly of our products all the time.

In the days of 21st century, we will be stricter with ourselves and have continuous technical innovation which will spur us on to higher quality products for our users. Customers at home and abroad are sincerely invited to visit, call and hold talks on internet.