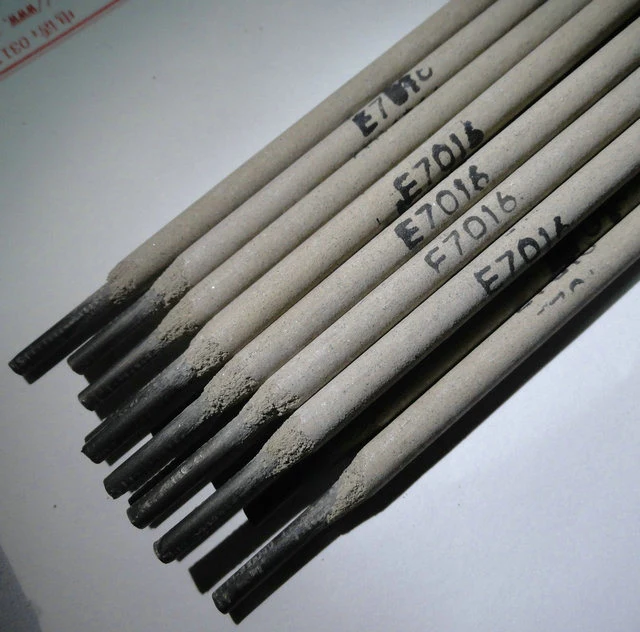

E7015 welding rods

Characteristics and Application:

TOKO E7015 is a low hydrogen type stick electrode for the welding of 490N/mm2 high tensile steel, and it is good for all-position welding. The welding features are (1)the arc is stable (2) less spatter (3) the slag covering is good (4) radiographic test result is good. It is specialized in back welding.

Typical Chemical Composition of Welding Metal:

Typical Mechanical Properties of Welding Metal:

Notes on Usage :

Sizes Available and Recommended Parameters:

Characteristics and Application:

TOKO E7015 is a low hydrogen type stick electrode for the welding of 490N/mm2 high tensile steel, and it is good for all-position welding. The welding features are (1)the arc is stable (2) less spatter (3) the slag covering is good (4) radiographic test result is good. It is specialized in back welding.

Typical Chemical Composition of Welding Metal:

| Alloy wt % | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| AWS | 0.15 | 1.60 | 0.75 | 0.20 | 0.30 | 0.30 | 0.035 | 0.035 | 0.08 |

| GEL-56U | 0.06 | 0.06 | 0.25 | 0.012 | 0.01 | 0.01 | 0.007 | 0.007 | 0.003 |

Typical Mechanical Properties of Welding Metal:

| Y.S. (MPa) | T.S.(MPa) | El (%) | CVN(J/°C) | |

| AWS | 400 | 490 | 22 | 27/-30 |

| GEL-56U | 445 | 540 | 34 | 50/-30 |

Notes on Usage :

- Dry the stick electrodes at 350°C for one hour before welding.

- Be sure to remove moisture. Oil and rust on the base metal.

- To avoid blowhole when striking the arc, please use backstep method during welding.

- Keep short arc length when welding.

- Current type: DC or AC.

Sizes Available and Recommended Parameters:

| Diameter (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |

| Current (Amp) | F,H | 55-85 | 90-130 | 130-180 | 180-240 |

| OH,V | 50-80 | 90-120 | 130-160 | --- | |